Batteries Don’t Die; They Just Pile Up—Until Now

Electric vehicles (EVs) are rolling out of factories at breakneck speed, promising cleaner air and quieter streets. But here’s the catch—what happens when all those batteries run out of juice? Spoiler: It’s not pretty. EV batteries, after powering our Teslas and Rivians for a few years, become hazardous waste, ready to explode or leak toxic chemicals if improperly handled. By 2035, we’ll be looking at 150 million retired EV batteries piling up—a mountain of hazardous material waiting to create an environmental nightmare.

Battery recycling is nothing new, but the process has been a nightmare of its own. Current methods are clunky, energy-guzzling, and environmentally costly. Enter Princeton NuEnergy (PNE), a startup spun out of Princeton University, with a plasma-powered solution that aims to revolutionize the recycling game. What if those dead batteries could become the building blocks for the next generation of EVs without burning through natural resources? Let’s dive into the future where trash becomes treasure—thanks to Princeton’s plasma-assisted recycling technology.

This solution, initially covered in Interesting Engineering, is more than just an upgrade—it’s the first step toward making EVs sustainable from cradle to grave.

The EV Battery Problem: A Growing Environmental Time Bomb

EV batteries are classified as hazardous waste by the EPA. They contain lithium, nickel, cobalt, and other metals that make them prone to explosion if mishandled. Dumping them in landfills isn't just lazy—it’s dangerous. Toxic chemicals can seep into soil and groundwater, posing risks to nearby communities. And the real kicker? Extracting lithium from the ground generates tons of brine and pollution, wasting energy and resources.

But recycling batteries isn’t a walk in the park either. Extracting useful metals from dead batteries is energy-intensive, often requiring high heat (pyrometallurgy) or chemical leaching (hydrometallurgy). Both methods create nasty emissions, leaving us stuck between choosing environmental damage upfront or down the line.

Here's the math that makes recycling essential:

- Extracting one ton of lithium from ore requires 250 tons of rock and generates 750 tons of brine.

- The same ton of lithium can be recovered from just 28 tons of used batteries.

So why is only 5% of EV batteries currently recycled? Because traditional recycling processes are so inefficient, they barely make economic sense. This is where Princeton NuEnergy’s plasma-assisted recycling comes in, promising cleaner, cheaper, and faster recovery.

Traditional Recycling: Burning Through Resources

The Shred-and-Burn Routine

Most batteries today are shredded into bits and reduced to black mass—a gritty mix of shredded cathodes and anodes. From there, two options emerge:

- Pyrometallurgy: Smelting the black mass at over 2,900°F to extract metals.

- Hydrometallurgy: Leaching metals with acid.

Both methods are far from perfect. Pyrometallurgy is fossil-fuel-intensive, and hydrometallurgy requires massive amounts of water and chemicals, only to recover metals incompletely. Toxic gases like nitrous oxide and sulfur dioxide are just the cherry on top.

Plasma to the Rescue: PNE’s Low-Temperature Magic

What Is LPAS (Low-Temperature Plasma-Assisted Separation)?

Princeton NuEnergy has flipped the recycling script with low-temperature plasma-assisted separation (LPAS). Here’s how it works: Instead of burning or soaking battery materials in acid, LPAS uses plasma to create highly reactive ions that strip impurities from cathodes and anodes, rejuvenating them for reuse. Think of it as a battery spa day—without the fossil-fuel-powered sauna.

By keeping electron temperatures high but molecular temperatures low, LPAS makes battery recycling more sustainable. This technology isn’t just kinder to the environment—it’s cost-effective, too.

The Micro-Molten Shell: Repairing Battery Materials

The heart of PNE’s process lies in something called Micro-Molten Shell-Assisted Lithiation (MSAL). This mouthful of a technique restores aged battery materials to their former glory. MSAL coats depleted cathode surfaces with a thin lithium shell, repairing structural damage and restoring electrochemical performance. In short, it gives dead batteries a second life that rivals brand-new materials.

Why LPAS Is a Game-Changer

Environmental and Economic Benefits

PNE’s plasma technology slashes the environmental impact of battery recycling:

- 73% less energy consumption.

- 69% fewer carbon emissions.

- 69% less water used compared to traditional mining.

Beyond the environmental perks, it’s a financial win, too. Recycling with LPAS costs 38% less than producing new materials from scratch, thanks to fewer chemicals, lower energy use, and reduced waste handling.

And let’s not forget disposal costs—companies save big by recycling instead of paying for hazardous waste disposal. As Jon Williams, CEO of energy storage company Viridi, points out, recycling isn’t just good for the planet—it offers a powerful ROI opportunity.

Beyond Lithium: Versatility Across Battery Types

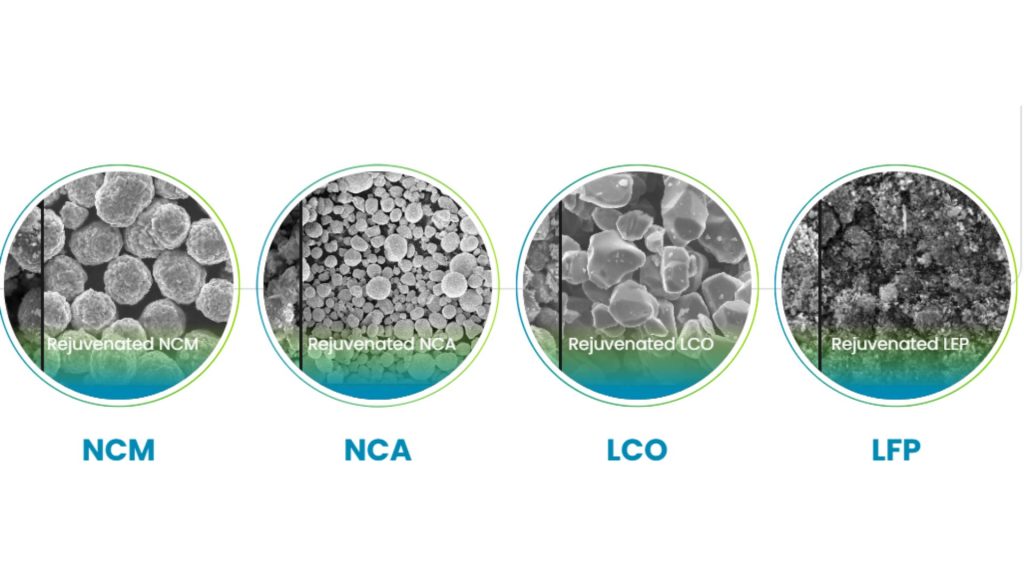

PNE’s LPAS technology isn’t picky. It works across a range of battery chemistries, including:

- Nickel-Cobalt-Manganese (NCM)

- Nickel-Cobalt-Aluminum Oxide (NCA)

- Lithium Iron Phosphate (LFP)

- Lithium Cobalt Oxide (LCO)

These chemistries power everything from electric cars to consumer electronics, making PNE’s solution scalable across industries. Tests show that LPAS-recycled batteries retain up to 88.9% of their original capacity after 1,000 charging cycles—a performance on par with batteries made from virgin materials.

Scaling the Future: From Lab to Mass Production

PNE isn’t just playing with lab experiments—they’re scaling up fast. After a successful prototype at Princeton’s Chemical and Biological Engineering lab, the company is building the first commercial-scale lithium-ion battery recycling facility in South Carolina. Expected to go live by 2028, the plant will churn out 10,000 tons of battery-grade material annually—enough to power 100,000 EVs each year.

This plant could set the stage for a recycling revolution, proving that plasma-assisted recycling can work not just in theory but in practice. If PNE pulls this off, it could become the gold standard for battery recycling in the US and beyond.

The Road to a Sustainable Future

Princeton NuEnergy’s plasma-based recycling technology is more than just a cool science experiment—it’s a glimpse into the future of sustainable energy. If EVs are going to replace gas-guzzlers, we need a way to recycle their batteries without trashing the planet in the process. Plasma-assisted recycling offers a cleaner, cheaper, and faster way to close the loop on EV batteries, ensuring that today’s trash becomes tomorrow’s treasure.

But the real challenge is scaling this technology fast enough to meet the growing demand. Will PNE’s plasma plant be the tipping point that makes sustainable battery recycling mainstream? Or will traditional methods continue to hold the industry back?

What do you think? Are plasma-powered recyclers the solution we’ve been waiting for, or is this just another tech trend with good PR? Join the conversation in the comments and become part of the “Shining City on the Web”. Share your thoughts, debate with other readers, and help shape the future of sustainable energy.

Disclaimer: This article may contain affiliate links. If you click on these links and make a purchase, we may receive a commission at no additional cost to you. Our recommendations and reviews are always independent and objective, aiming to provide you with the best information and resources.

Get Exclusive Stories, Photos, Art & Offers - Subscribe Today!

Post Comment

You must be logged in to post a comment.